Timber Framing

This

is the mill in Chehalis where our timbers were milled.

The

owner, Tim Rogerson uses a Wood Miser LT40 bandsaw to mill the

wood.

The

mill owner uses his tractor to help load the timbers.

8-16-10

Dan and Dan Z. loading the timbers on our trailer.

Dan and Dan Z. loading the timbers on our trailer.

8-17-19

Dan and son Dan unloading the timbers at home.

(Where's that tractor ???)

Dan and son Dan unloading the timbers at home.

(Where's that tractor ???)

Nothing

easy about this job.

Bullwinkle

likes the new timbers.

Three

loads completes the timber order for the shop building.

A

cousin of Dan's once told us that what a guy living in the Great Northwest

really needs is an acre with a roof over it. That could come in handy now with

fall in the air.

Dan's

chisels ready for his first project. He is going to build a set a saw horses to

give himself a little practice at timber framing.

He

uses his power saw for as much of the cut as he can.

And

finishes the cut with his hand saw.

With

a firm bap the excess wood from around the tenon comes off.

Then

just a little clean up with the chisel.

After

the mortise is marked out and the corners drilled......

he

uses his power drill to remove the bulk of the wood.

Then

chisels out the remaining wood.

A

corner chisel makes nice crisp corners.

Although

the mortise and tenon joint is one of the easier joints in timber framing, if it

is not correct, the pieces will not fit together correctly.

Oh

good. The brace tenon fits the leg mortise.

And

the leg tenon fits in the foot mortise.

Then

holes are drilled though the mortise for the pegs or "wooden nails".

The tenon is put into the mortise and the hole is marked.

The tenon is put into the mortise and the hole is marked.

Then

Dan drills the hole in the tenon slightly off center so when he drives the peg

in, it draws the pieces tight. This technique is called "draw boring".

This

baby is rock solid!

The

pegs can be cut flush or left a little proud.

Dan

routes the edges of the pegs and timbers for a final touch.

Nice

saw horses. Now lets build a shop.

The

timbers are brought into the small shop and planed and sanded (thanks

Mike).

Then

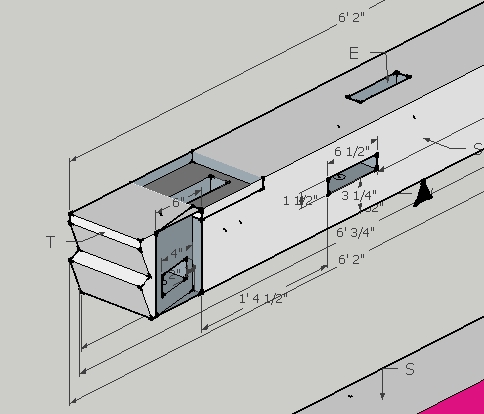

using a plug in program to Google Sketchup, created by Clark Bremer, I make

a timber cutting plan.

Dan

has some how figured out how to cut these joints. These are two of the posts

with their many different joints.

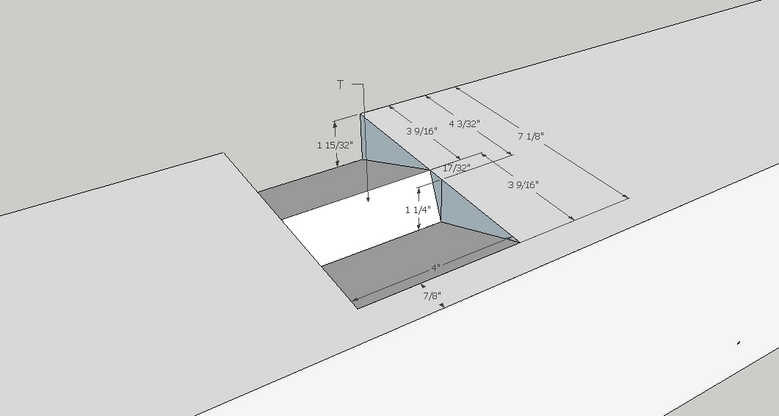

This

joint is called a "step-lap rafter seat". This one is located

in a girt.

After

each piece is completed it is labled to later be assembled in its frame.

One

of the tools Dan uses is called a Miller Falls Boring Machine. It is used for

boring holes for the large mortises. They don't make these anymore, but Dan

found a guy, Tom Perkins, who reconditions antique ones and sells

them.

It's

a good thing Dan enjoys working in the shop or this could seem like work.

The

posts are the most difficult parts to make, and it takes most of the day to make

one.

There

are beautiful timbers hiding in this pile of logs.

We took a

little break for hunting season, holidays, and because we were feeling

a little burned out. Dan got back out in the shop working on the timbers for

most of January. Today he starts his tax season work so everything is now on

hold till mid April.

9-14-10

Back to 2010